Sir Meccanica Line Boring and Welding Overlay Machines

IMS offers a unique and high quality in all of our products and services from the following:

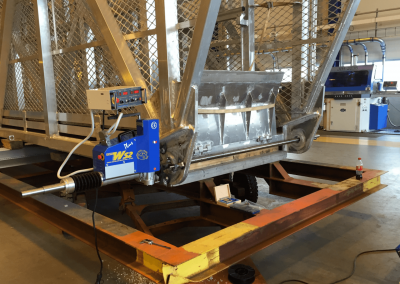

Sir Meccanica W Series

W Series are the only ones that perform line boring, overlay welding (internal and external, also on blind holes), drilling and tapping with just one machine in one single set-up:

- Boring diameter: from 0,87” up to 66,93”.

- Welding diameter: from 0,98” up to 66,93”.

The centering of the machine is appreciated for its simplicity and can be mounted within 10-15 minutes. The boring stroke is unlimited. W Series is manipulated through self-centering connectable shafts with conical coupling and its tool holder extensions with conical coupling as well.

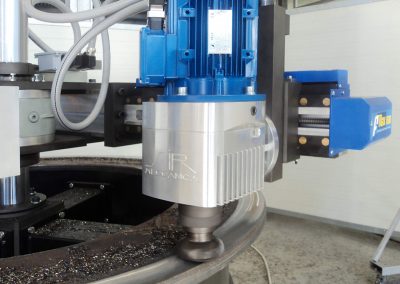

W Full CNC

W Full CNC is a one of a kind machine in which we have no other competition. It is unique of its kind. It has all the advantages of the W Series machine tools that are enhanced with a CNC head, which allows the machine to perform any profile, including the overlay welding.

- Working diameter: from 4,33” up to 23,62”.

It performs all the machining jobs similar to our W Series to do a curvilinear profile with any tips of radius, conical machining, any type of chamfer, all types of threading, simple and shaped facing, any type of grooving, and phonographic grooves.

TOP Series

TOP Series is also a unique and one of a kind machine in the world of industrial machinery. Its portable orbital lathe is completely run by a CNC control panel to work with extreme precision. This machine performs the following:

- Rectilinear and/or curved profile interpolations,

- Multilevel grooves,

- Standard and/or tapered threading,

- Profile facing

TOP Series has a maximum working diameter of 15,74”.

FMax Series

FMax Series is a portable facing lathe/milling machines which are controlled by an electronic control panel to perform diverse machining jobs on the faces of large cylindrical tubing, in achieving an unprecedented finish and accuracy results. They can work in any position: horizontal, vertical and inclined. The FMax Series is also available with a CNC controller (FMax 800 and FMax 2000 Models). This machine performs the following:

- Milling,

- Turning operations,

- Contouring,

- Calibrated drilling on circular series,

- Tapping on circular series,

- Creation of circular pockets,

- Circular mig welding,

- Circular oxygen cutting

FMax Series has a diameter facing from 13,78” up to 236,22”.

High-Quality Sir Meccanica Services

You will never go wrong in choosing our services. At IMS & DBH, we offer only the best quality and most professional machining performance on line boring and welding overlay machines. You don’t have to look further for a world class and quality services from any other company and or repair shops. At IMS & DBH, we can deliver it right to your doorstep. Once you give us a go ahead, our personnel will readily render their services immediately with no ifs, ands or buts.

Our services can spare you and your company from all the additional costs and hassles of going back and forth to the repair shop. The fact that we have portable line boring machines, we can do repairs on-site which means that the equipment that has to be repaired doesn’t need to be dismantled and to be transported in a specialized workshop anymore and we can deliver it quickly wherever it may be. Above all, our services are truly remarkable from eliminating downtime and costly expenses. So, keep a handy line boring tools available at all times or you can call us to give you a hand with our line boring equipment.

Our Key Staff Members

Anthony Davison

President

KARTER PORTER

Technical Director

SAM NOE

Outside Sales

IMS & DBH is a premier and leading company that has been in the industry for more than 25 years and continually offers quality brands, products, and services worldwide. We have a remarkable presence throughout the globe with our beneficial and considerable after sale-services and warranty of our products. We provide a world-class and professional machining performance with our top notch line boring and welding overlay machines and other services.

As the premier industry for repairs and restoring your machinery, we can certify and guarantee you only the highest and quality standards of our products and services. Our personnel has continually adhered to professionalism in their specialized crafts and these acknowledgments gave us a considerable amount of certifications and recognitions.

We have the most important ones which are the UNI-EN-ISO 9001; EC (N ° IMQ 192) for the WS Series; CE certification; GOST; The NATO Code (NCAGE AFA 74) which recognizes the company as an official supplier of materials and services to the United States Government and the American bases in Europe. Our products are granted by the excellence and distinction—Made in Italy.

Do not hesitate to contact us; this is an opportunity that you don’t want to go to waste. You can give us a call today for a quote regarding on our line boring and welding overlay machines and to find out more about our trusted brands, products, and world class services.

Why do you need our Sir Meccanica services?

Planning on giving your equipment and machinery regular preventive measures? At IMS, we will provide you world-class services for all your industrial needs.

In maintaining your industrial equipment and machinery, it should be done regularly to avoid any major issues along the way and this can also eliminate major downtime at work and costly repairs once your equipment will fully shut down on you. These are few of the important details in keeping your machines to its tip top shape:

- Always keep it lubricated – all machinery and equipment create friction.

- Keep it clean – by removing any dirt and debris.

- Inspect and repair – consistency on checking up your equipment regularly keeps your business running. So, keep a handy line boring tools at all times.

- Pay attention to the slightest details – do not overlook any wear and tear because it might lead to a costly repair and eventually requires a new machine.

- Train your personnel – to keep your business and equipment to its tip top shape is to have your employees trained.

Detecting early the potential defects from your equipment will spare you greatly from all the hassles and expenses. Ensuring your equipment if it is running smoothly and produces on a regular basis should be your top priority.

Feel Free to Contact Us

Please call us! We would be happy to hear from you and we love to answer any questions you might have about our current products or services; industrial machine servicing; line boring equipment; Pneumatic Cylinders; MIG Welding Products & Supplies; Steel Hydraulic Fittings; Electric Motors and Controls; Paint Booths; Air Logic Controls; Spray Booth Paper; Hose Reels; Hydraulic Pumps; Pneumatic Compressors; Specialty Welding; CNC Parts, and many more services than we can list.

You can call us at this telephone number: 901-348-1155

You can reach our fax machine at this telephone number: 901-348-0373

Or if you would rather email us in order to request parts from DBH Distributors, Inc., please click here and fill out our quick form and we will be sure to get back to you as soon as we can. And for more generalized inquiries, you can always click here and fill out our simple form. We will answer your inquiry as soon as we are able to.

If you would like to visit, we are conveniently located at

3325 Millbranch Road

Memphis, TN, 38116

We are right near where Route 55 and Route 240 meet, less than ten miles south of Memphis.

Our business hours are Monday thru Friday 7:00 AM – 3:30 AM